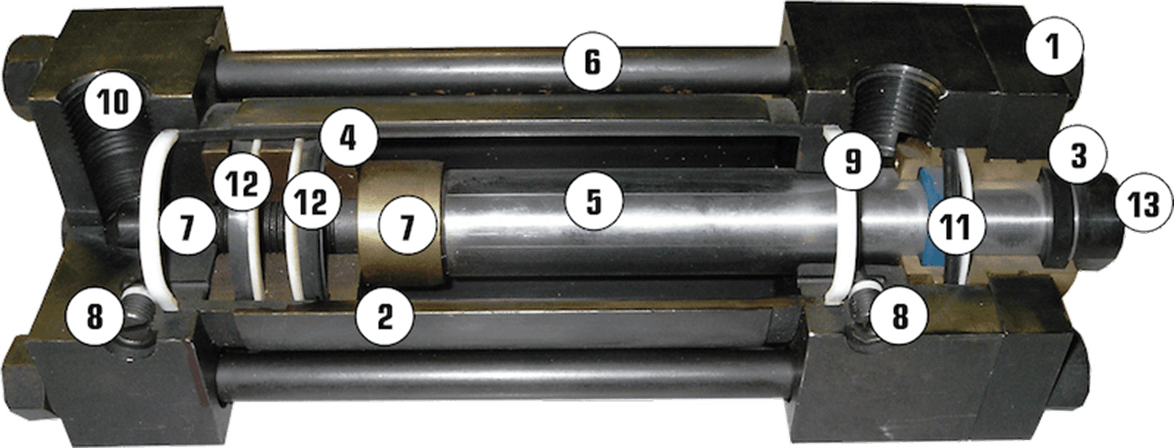

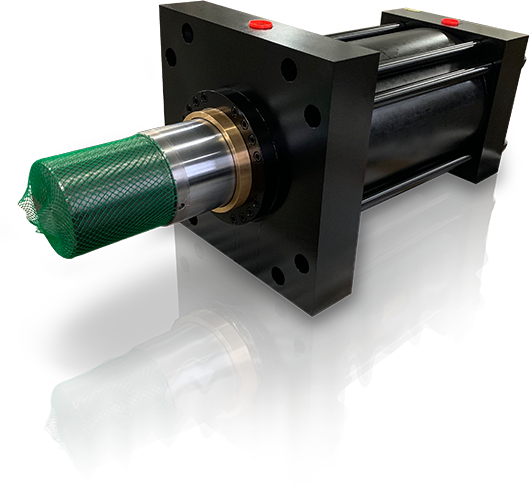

1. Head/Cap: Precision machined steel head ad cpa provide close concertricity and accurate alignment between piston, tube, piston rod and rod bearing.

2. Cylinder Barrel: Damage resistant, heavy wall steel tubing, honed to an 8 to 16 micro finish for low frictional drag and maximum seal and pisto bearing life.

3. Rod Certridge: Extra long, high strength bronze gland provides maximum bearing support and wear resistance. With certain exceptions, a removable retainer allows for gland removal without cylinder disassembly.

4. Piston: One piece fine grained cast iron piston provides maximum strength and protection against shock loads. Anaerobic adhesive is used to permanently lock and seal the piston to the rod.

5. Piston Rod: One piece fine grained cast iron piston provides maximum strength and protection against shock loads. Anaerobic adhesive is used to permanently lock and seal the piston to the rod.

6. Tie Rode: 100,000 to 125,000 PSI minimum yield steel, pre-stressed for fatigue resistance, and roll threaded for added strength.

7. Cushions: Head cushion sleeve and rear cushion spear are machined to close tolerances to provide a gradual deceleration and reduced shock at end of stroke.

8. Cushion Needle Adjustment & Bell Check: Flush mounted captive cushion adjustment allows for safe cushion adjustment under pressure. Special tip design and fine threads allow for precise adjustment over a broad range of operations. Cushion ball check allows for fast break-away under full power.

9. Tube End Seals: Flush mounted captive cushion adjustment allows for safe cushion adjustment under pressure. Special tip design and fine threads allow for precise adjustment over a broad range of operations. Cushion ball check allows for fast break-away under full power.

10. Ports: Flush mounted captive cushion adjustment allows for safe cushion adjustment under pressure. Special tip design and fine threads allow for precise adjustment over a broad range of operations. Cushion ball check allows for fast break-away under full power.

11. Rod Seals: Twin lip urethane rod seal is pressure energized and wear-compensating for long, leak-free service. Viton® seals are optional.

12. Piston Seals: Pressure energized nitrile U-cups with back-up rings are standard. Step cut cast iron rings and Viton® seals are optional.

13. Rod Wiper: Pressure energized nitrile U-cups with back-up rings are standard. Step cut cast iron rings and Viton® seals are optional.

CLICK HERE to visit our Cylinder Configurator.

CLICK HERE to visit our Cylinder Configurator.