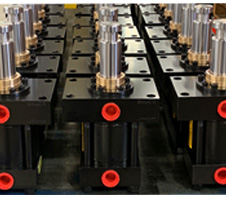

Yates NFPA Tie Rod Cylinders Are Built to Outperform

Interchangeability

When you’re looking for a reliable tie rod cylinder from heavy-duty to light-duty hydraulics and pneumatics,

Yates has one that's sure to fit your needs.

- Bore Size From 1.5" - 24"

- 23 Different Mount Types

- NFPA, JIC Interchangeability

- 3 Year Limited Warranty

- Specials to 50" Dia. Bore & Lengths over 48" in length

Heavy Duty Hydraulic (H6)

- Bore sizes from 1.5" - 24", 20 mounting styles

- JIC-NPA Interchangable

- 3,000 PSI

Pnuematic Heavy Duty (A4) Hydraulic Medium Duty (H4) Pneumatic Permanently Lubricated L4

- Bore sizes from 1.5" - 20", 20 mounting styles

- JIC-NPA Interchangable

- Pressure up to 250 PSI pneumatic or 400 PSI Hydraulic

Pneumatic (A2) Hydraulic Light Duty (H2)

- Bore sizes from 1.5" - 8", 20 mounting styles

- JIC-NPA Interchangable

- Pressure up to 250 PSI pneumatic or 400 PSI Hydraulic

Flexibility

Ideal for demanding foundry, steel mill, plastics, and stamping industries. Tie rod cylinder application range from clamping, shearing and forging, to bending, press, and counterbalance. All our tie rod cylinders are manufactured with pride at our St. Clair Shores, Michigan facility.

Cylinder Features and Specs:

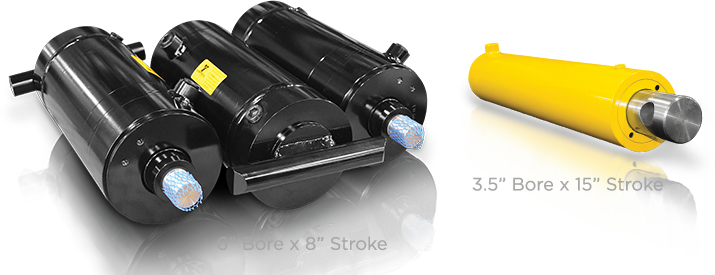

Yates Welded Hydraulic Cylinders Are Built for Performance and Reliability

Interchangeability

Yates has a wide range of rugged, sturdy, and dependable welded-body cylinders designed to meet industry equipment demands.

Hydraulic Heavy Duty (WH)

- Bore Sizes From 1.5" - 18" with Screw in gland

- CPO Rod

- 3,000 PSI

Hydraulic Medium Duty (WM)

- Bore Sizes From 1.5" - 18" with Snap Ring Gland

- CPO Rod

- 1.800 - 2,500 PSI

Pneumatic (WP)

- Bore Sizes From 1.5" - 18" with Snap Ring Gland

- CPO Rod

- 2,500 PSI

Special Cylinders available per customer requirements.

Suitability

Yates welded hydraulic cylinders perform in a vast range of manufacturing applications. Manufactured exclusively at our Austell, Georgia facility, our welded cylinder are ideal for your medium and heavy duty applications, including packing and extreme milling.

Cylinder Features and Specs:

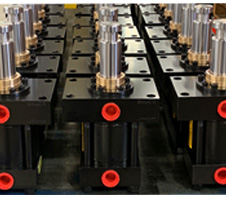

With Yates Mill Duty Hydraulic and Pneumatic Cylinders, Your Factory Floor Has Met Its Match

Durability

Yates manufactures a workhorse of a mill duty cylinder - dsigned to work under extreme pressure and physical wear while meeting all of your production needs.

Hydraulic Severe Duty (WS)

- Bore Size From 4" - 24"

- Increase wall tubing

- IHCP Rod

- 3,000 PSI

- Built for extreme applications

Heavy Duty Hydraulic Mill (MH)

- 6 Mounting Styles

- Bore sizes from 2" - 24" with IHCP Rod

- 3,000 PSI

- Built for extreme mill applications

Pneumatic Mill Duty (MP)

- 6 Mounting styles

- Bore Sizes From 2" - 24" with CPO Rod

- 250 PSI

Special Cylinders available per customer requirements.

Accessibility

They are manufactured with pride at our Alabama facility in Decatur, our mill duty cylinders feature high load piston design, heavy wall tubing, and induction hardened, chrome plated rods. Yates solid mill duty cylinders are built tough to keep on performing.

Cylinder Features and Specs:

Yates Accessories - Ensuring You Have the Perfect Fit Every Time

Accessories are a crucial part of a complete cylinder solution. Offering a wealth of brackets, pins, rod eyes, couplers and other parts, Yates ensures that every cylinder fits safe and snug.