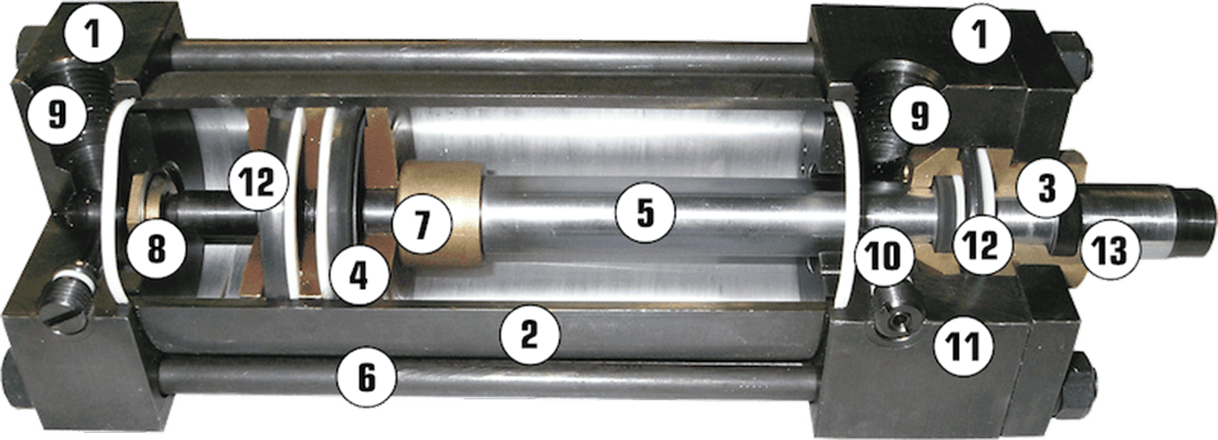

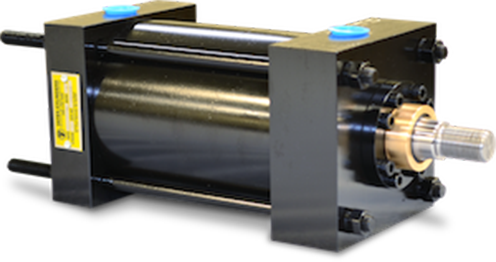

1. Head / Cap: Precision machined steel head and cap provide close concentricity and accurate alignment between piston, tube, piston rod and rod bearing.

2. Cylinder Barrel: Damage resistant tubing honed to an 8 to 16 micro finish for low frictional drag and maximum seal life. Hard chrome plated to resist corrosion and scoring.

3. Rod Cartridge: Extra long, high strength bronze gland provides maximum bearing support and wear resistance. With certain exceptions, a removable retainer allows for gland removal without cylinder disassembly.

4. Piston: One piece fine grained cast iron piston provides maximum strength and protection against shock loads. Anaerobic adhesive is used to permanently lock and seal the piston to the rod.

5. Piston Rod: High strength, damage resistant piston rod provides 100,000 PSI minimum yield material in 5/8” through 4 1/2” diameters. Larger diameters vary between 50,000 and 75,000 PSI minimum yield material. All rods are case hardened to 50-55 RC and hard chrome plated to provide maximum wear life. Stainless steel is also available.

6. Tie Rods: 100,000 to 125,000 PSI minimum yield steel, pre-stressed for fatigue resistance, and roll threaded for added strength.

7. Head Cushions: Self centering head cushion design provides consistent cushioning performance.

8. Cap Cushins: Floating cap cushion insert design replaces ball check to provide greater flow area for fast break-away and provides consistent cushioning performance.

9. Cushion Needle Adjustment & Ball Check: Flush mounted captive cushion adjustment allows safe cushion adjustment under pressure. Special tip design and fine threads allow precise adjustment over a broad range of operations. Cushion ball check provided at head end allows for fast break-away under full power.

10. Tube Seals: Extrusion resistant Teflon® material is compatible with virtually all fluids and can operate in temperatures to 500°F.

11. Ports: NPTF ports are standard and can be rotated to any 90 degree position in relation to each other and the mounting. SAE ports optional.

12. Rods and Piston Seals: Pressure energized nitrile U-cups, with back-up rings are standard. Step cut cast iron rings and Viton® seals for temperatures to 400°F are optional. Special seals for low friction, high speed applications are also available.

13. Rod Wiper: Nitrile double lip rod wiper acts as secondary seal while keeping out dirt, dust and other contaminants. Optional Viton® wiper available for fluid compatibility or temperatures to 400°F. Metallic scrapers and low friction wipers also available.

CLICK HERE to visit our Cylinder Configurator.

CLICK HERE to visit our Cylinder Configurator.